RV Slide-Out Maintenance: Keeping Them Working Smoothly

Understanding RV Slide Outs A Comprehensive Overview

RV slide outs are a marvel of engineering, transforming a compact living space into a surprisingly roomy home on wheels. These extendable sections significantly increase the square footage of your RV, making them a crucial feature for many RVers, especially those who travel full-time or enjoy extended stays. But with this added convenience comes the responsibility of proper maintenance. Ignoring slide out maintenance can lead to costly repairs and frustrating disruptions to your travel plans.

Let's delve into the different types of RV slide outs you might encounter:

- Electric Slide Outs: These are the most common type, powered by an electric motor. They're generally reliable but can be susceptible to issues related to the motor, wiring, or gears.

- Hydraulic Slide Outs: Found in larger and more luxurious RVs, hydraulic slide outs use hydraulic fluid and a pump to extend and retract the slide. They're known for their strength and ability to handle heavier loads.

- Manual Slide Outs: Less common in newer models, manual slide outs require you to physically crank the slide in or out. While they're less convenient, they're also less prone to mechanical failures.

No matter what type you have, understanding the basic mechanics of your RV slide out is the first step in ensuring its longevity and smooth operation.

Essential RV Slide Out Lubrication Techniques and Best Practices

Lubrication is the single most important aspect of RV slide out maintenance. Just like any mechanical system, the moving parts of your slide out need regular lubrication to prevent friction, wear, and corrosion. Without proper lubrication, you'll likely experience jerky movement, squeaking, and eventually, damage to the gears, tracks, or rollers.

Choosing the Right Lubricant: This is where many RVers make mistakes. You can't just use any old lubricant! You need a lubricant specifically designed for RV slide outs. These lubricants are typically dry-film lubricants, which means they leave a thin, non-sticky coating that won't attract dirt and debris. Avoid using greasy or oily lubricants, as they will quickly accumulate dirt and grime, leading to accelerated wear.

Recommended Lubricants:

- 3-IN-ONE RVcare Slide-Out Silicone Lube: A popular and widely available option. It's a dry-film silicone lubricant that's easy to apply and provides excellent protection. You can find it for around $10-$15 per can at most RV supply stores or online retailers like Amazon.

- Protect All Slide-Out Dry Lube: Another excellent choice, known for its long-lasting protection and ability to reduce friction. It's a bit more expensive than the 3-IN-ONE option, typically costing around $15-$20 per can.

- Lippert Components Slide-Out Lubricant: Specifically designed for Lippert slide out systems (a common manufacturer), this lubricant is a great option if you want to stick with the manufacturer's recommendation. Expect to pay around $20-$25 per can.

How to Lubricate Your Slide Out:

- Clean the Slide Out Mechanism: Before applying any lubricant, thoroughly clean the slide out mechanism. Use a brush and a mild soap and water solution to remove any dirt, debris, or old lubricant. Allow the area to dry completely.

- Identify the Lubrication Points: Refer to your RV's owner's manual to identify the specific lubrication points on your slide out mechanism. These typically include the gears, tracks, rollers, and any other moving parts.

- Apply the Lubricant: Apply the lubricant sparingly to the identified lubrication points. Avoid over-lubricating, as this can attract dirt and debris.

- Cycle the Slide Out: After applying the lubricant, cycle the slide out in and out several times to distribute the lubricant evenly.

- Wipe Away Excess Lubricant: Use a clean cloth to wipe away any excess lubricant.

Lubrication Frequency: How often should you lubricate your slide out? This depends on several factors, including how often you use your RV, the climate you're traveling in, and the type of slide out you have. As a general rule of thumb, lubricate your slide out at least every three months or after every major trip. If you're traveling in dusty or wet conditions, you may need to lubricate it more frequently.

RV Slide Out Alignment Problems Diagnosing and Solutions

Slide out misalignment can manifest in various ways, from difficulty extending or retracting the slide to visible gaps around the slide when it's fully extended. Ignoring these symptoms can lead to more serious problems, such as water leaks, structural damage, and even complete slide out failure.

Common Causes of Slide Out Misalignment:

- Uneven Ground: Parking your RV on uneven ground can put stress on the slide out mechanism and cause it to become misaligned.

- Excessive Weight: Overloading your slide out with too much weight can also lead to misalignment.

- Worn Rollers or Tracks: Over time, the rollers or tracks that support the slide out can wear down, causing it to sag and become misaligned.

- Loose Fasteners: Loose bolts, screws, or other fasteners can also contribute to slide out misalignment.

- Frame Flex: In some cases, the RV's frame itself may flex or warp, causing the slide out to become misaligned.

Diagnosing Slide Out Misalignment:

- Visual Inspection: Start by visually inspecting the slide out mechanism for any signs of damage, wear, or loose fasteners. Look for gaps around the slide when it's fully extended.

- Listen for Unusual Noises: Pay attention to any unusual noises, such as grinding, squeaking, or popping, when you extend or retract the slide out.

- Check the Slide Out Travel: Observe how smoothly the slide out extends and retracts. Does it move evenly, or does it jerk or bind in certain spots?

- Use a Level: Use a level to check the alignment of the slide out relative to the RV's frame.

Solutions for Slide Out Misalignment:

- Level Your RV: Always level your RV before extending the slide outs. Use leveling blocks or automatic leveling systems to ensure that the RV is perfectly level.

- Distribute Weight Evenly: Avoid overloading your slide outs with too much weight. Distribute the weight evenly throughout the RV.

- Tighten Loose Fasteners: Check all the bolts, screws, and other fasteners on the slide out mechanism and tighten any that are loose.

- Adjust Slide Out Rollers or Tracks: Some slide out systems have adjustable rollers or tracks that can be used to correct minor misalignment issues. Refer to your RV's owner's manual for instructions on how to adjust these components.

- Replace Worn Rollers or Tracks: If the rollers or tracks are worn down, they will need to be replaced. This is a more involved repair that may require the assistance of a qualified RV technician.

- Consult a Professional: For more serious misalignment issues, it's best to consult a qualified RV technician. They have the expertise and tools to diagnose and repair complex slide out problems.

RV Slide Out Seal Maintenance Preventing Water Leaks and Damage

RV slide out seals are critical for preventing water leaks, drafts, and insect infestations. These seals create a barrier between the interior and exterior of your RV, protecting it from the elements. However, over time, slide out seals can become damaged or worn, compromising their effectiveness.

Types of RV Slide Out Seals:

- Bulb Seals: These are the most common type of slide out seal, featuring a hollow bulb that compresses against the slide out flange to create a watertight seal.

- Wiper Seals: Wiper seals have a flexible lip that wipes against the slide out as it extends or retracts, removing water and debris.

- D-Seals: D-seals are shaped like the letter "D" and are often used in conjunction with other types of seals to provide an extra layer of protection.

Common Causes of Seal Damage:

- UV Exposure: Prolonged exposure to sunlight can cause the seals to dry out, crack, and lose their elasticity.

- Extreme Temperatures: Extreme heat or cold can also damage the seals, causing them to become brittle or warped.

- Abrasion: Friction from the slide out rubbing against the frame can wear down the seals over time.

- Debris: Dirt, leaves, and other debris can accumulate on the seals, preventing them from sealing properly.

Maintaining Your Slide Out Seals:

- Regular Cleaning: Clean your slide out seals regularly with a mild soap and water solution. Use a soft brush to remove any dirt, debris, or insect nests.

- Seal Conditioner: Apply a seal conditioner specifically designed for RV slide out seals. These conditioners help to keep the seals supple and prevent them from drying out and cracking. 303 Aerospace Protectant is a highly recommended product for this purpose, costing around $20-$25 per bottle. Its UV protectant properties are invaluable.

- Inspect for Damage: Inspect your slide out seals regularly for any signs of damage, such as cracks, tears, or gaps. Replace any damaged seals immediately.

- Lubricate the Seals: Lubricate the seals with a silicone-based lubricant to reduce friction and prevent them from sticking.

- Protect from UV Exposure: When your RV is not in use, park it in a shaded area or use RV covers to protect the slide out seals from UV exposure.

Replacing Damaged Seals:

Replacing damaged slide out seals is a relatively straightforward repair that can be done yourself. However, it's important to choose the correct replacement seals for your RV. Refer to your RV's owner's manual or contact the manufacturer to determine the correct seal type and size. You can find replacement seals at most RV supply stores or online retailers. The cost of replacement seals can vary depending on the type and size, but expect to pay between $20 and $100 per seal.

RV Slide Out Motor Repair Troubleshooting and Maintenance

The RV slide out motor is the powerhouse behind your slide out system. When it malfunctions, your slide out becomes unusable, rendering a significant portion of your RV's living space inaccessible. Understanding the common issues, troubleshooting techniques, and maintenance practices can save you from costly repairs and inconvenient breakdowns.

Common Slide Out Motor Problems:

- Motor Failure: The motor itself can fail due to overheating, wear and tear, or electrical issues.

- Wiring Problems: Loose connections, corroded wires, or damaged wiring can prevent the motor from receiving power.

- Gearbox Issues: The gearbox that transfers power from the motor to the slide out mechanism can become damaged or worn, causing the motor to struggle or fail.

- Low Voltage: Insufficient voltage from the RV's battery or charging system can prevent the motor from operating properly.

- Obstructions: Obstructions in the slide out mechanism, such as debris or frozen components, can put excessive strain on the motor.

Troubleshooting Slide Out Motor Problems:

- Check the Power Supply: Ensure that the RV's battery is fully charged and that the slide out motor is receiving adequate voltage. Use a multimeter to check the voltage at the motor terminals.

- Inspect the Wiring: Inspect the wiring connections to the motor for any signs of looseness, corrosion, or damage. Clean or repair any damaged connections.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the motor, such as grinding, clicking, or humming. These noises can indicate a problem with the motor or gearbox.

- Check for Obstructions: Inspect the slide out mechanism for any obstructions that may be preventing the slide out from moving freely.

- Test the Motor: If you suspect that the motor itself is faulty, you can test it by bypassing the RV's control system and applying power directly to the motor terminals. Be careful when doing this, as you could damage the motor if you apply the wrong voltage or polarity.

Slide Out Motor Maintenance:

- Regular Lubrication: Lubricate the slide out mechanism regularly to reduce friction and prevent the motor from working too hard.

- Protect from Moisture: Protect the motor from moisture and corrosion. If the motor is exposed to the elements, consider covering it with a waterproof cover.

- Avoid Overloading: Avoid overloading the slide out with too much weight, as this can put excessive strain on the motor.

- Proper Storage: When storing your RV, retract the slide outs to protect the motor and slide out mechanism from the elements.

Replacing a Faulty Slide Out Motor:

Replacing a faulty slide out motor is a more involved repair that may require the assistance of a qualified RV technician. However, if you're comfortable working with electrical systems and mechanical components, you may be able to do it yourself. The cost of a replacement slide out motor can vary depending on the type and size, but expect to pay between $100 and $500. You can find replacement motors at most RV supply stores or online retailers.

RV Slide Out Gear Repair Maintaining Smooth Operation

The gears within your RV's slide-out system are responsible for translating the motor's power into the movement that extends and retracts the slide. Just like any mechanical system, these gears are subject to wear and tear, requiring maintenance and occasional repair to ensure smooth and reliable operation.

Understanding Slide Out Gear Systems:

Different RV slide-out systems employ various gear mechanisms, including:

- Spur Gears: The most common type, featuring straight teeth that mesh together.

- Worm Gears: Offering high torque and self-locking capabilities, often used in heavier slide-out systems.

- Rack and Pinion Gears: Converting rotational motion into linear motion, often found in smaller slide-out units.

Common Gear Problems:

- Worn Teeth: Over time, the gear teeth can wear down due to friction and stress, leading to slippage and reduced efficiency.

- Broken Teeth: Excessive force or sudden impacts can cause gear teeth to break, rendering the slide-out system inoperable.

- Corrosion: Exposure to moisture and the elements can cause the gears to corrode, leading to stiffness and premature wear.

- Misalignment: Improper alignment of the gears can cause uneven wear and increased friction, leading to premature failure.

- Lack of Lubrication: Insufficient lubrication can cause the gears to overheat and wear down quickly.

Diagnosing Gear Problems:

- Unusual Noises: Listen for grinding, clicking, or popping noises when operating the slide-out. These noises can indicate worn or damaged gears.

- Jerky Movement: Observe the slide-out's movement for any signs of jerkiness or hesitation. This can be a sign of worn or misaligned gears.

- Difficulty Extending or Retracting: If the slide-out is difficult to extend or retract, it could be due to worn or damaged gears.

- Visual Inspection: Inspect the gears visually for any signs of wear, damage, or corrosion. Look for missing teeth, cracks, or rust.

Gear Maintenance:

- Regular Lubrication: Apply a high-quality gear lubricant to the gears regularly to reduce friction and prevent wear. Use a lubricant specifically designed for gear systems. White lithium grease is often recommended.

- Cleanliness: Keep the gears clean and free of dirt, debris, and corrosion. Use a brush and a mild solvent to clean the gears periodically.

- Alignment Checks: Check the alignment of the gears regularly to ensure that they are properly meshed. Adjust the alignment as needed.

- Inspect for Wear: Inspect the gears regularly for any signs of wear or damage. Replace worn or damaged gears promptly.

Gear Repair and Replacement:

Repairing damaged gears is often not feasible, as it requires specialized equipment and expertise. In most cases, it's more cost-effective to replace the damaged gears. Replacing the gears is a more involved repair that may require the assistance of a qualified RV technician. The cost of replacement gears can vary depending on the type and size, but expect to pay between $50 and $300 per gear. You can find replacement gears at most RV supply stores or online retailers.

RV Slide Out Roller Replacement Ensuring Smooth Movement

RV slide out rollers are the unsung heroes of your RV's expandable living space. These small but mighty components bear the weight of the slide out and allow it to move smoothly in and out. Over time, however, rollers can wear down, crack, or even disintegrate, leading to jerky movement, binding, and potential damage to the slide out mechanism. Replacing worn rollers is a crucial part of maintaining your RV's slide out system.

Types of RV Slide Out Rollers:

- Nylon Rollers: These are the most common type of roller, known for their durability and smooth rolling action.

- Steel Rollers: Steel rollers are stronger than nylon rollers and are often used in heavier slide out systems.

- Plastic Rollers: Plastic rollers are less expensive than nylon or steel rollers but are also less durable.

Signs of Worn or Damaged Rollers:

- Jerky Movement: The slide out moves unevenly or jerks as it extends or retracts.

- Binding: The slide out gets stuck or binds in certain spots.

- Squeaking or Grinding Noises: Unusual noises coming from the slide out mechanism can indicate worn rollers.

- Visible Damage: Inspect the rollers visually for any signs of cracks, chips, or flat spots.

- Uneven Slide Out Position: The slide out may not sit evenly when fully extended or retracted.

Replacing RV Slide Out Rollers:

Replacing RV slide out rollers is a relatively straightforward repair that can be done yourself with a few basic tools. However, it's important to choose the correct replacement rollers for your RV. Refer to your RV's owner's manual or contact the manufacturer to determine the correct roller type and size. You can find replacement rollers at most RV supply stores or online retailers. The cost of replacement rollers can vary depending on the type and size, but expect to pay between $10 and $50 per roller.

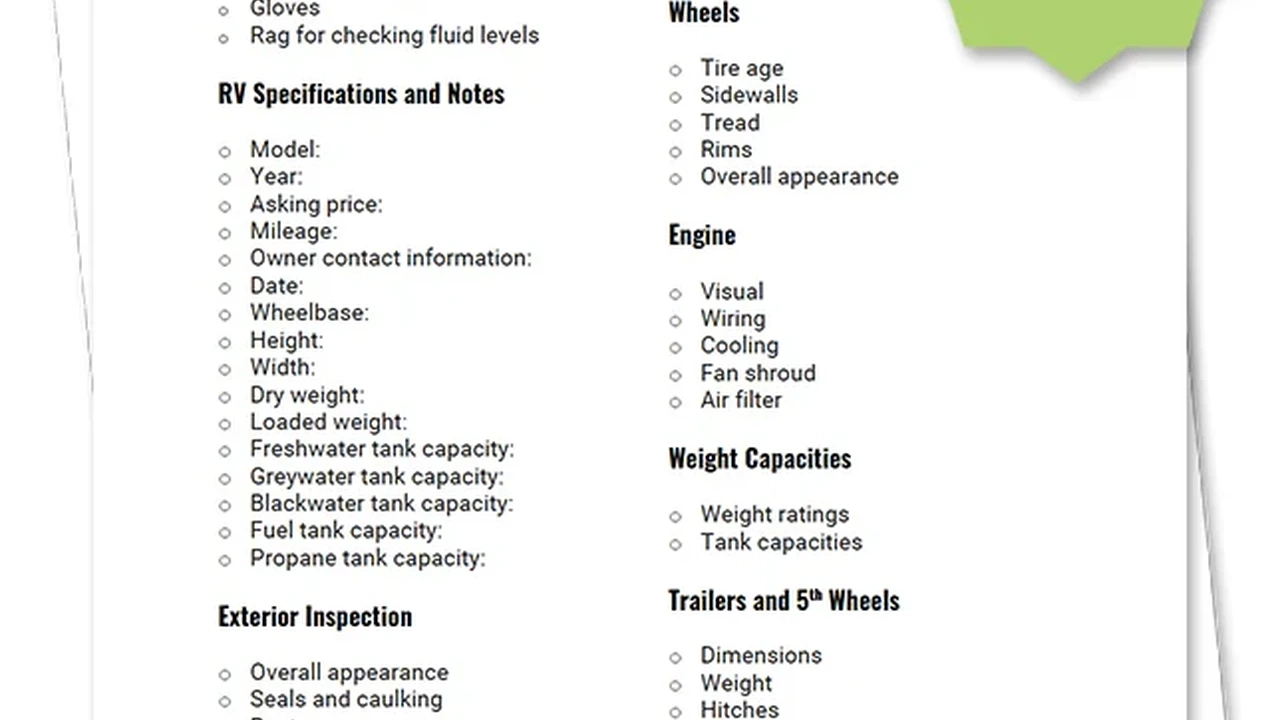

Tools You'll Need:

- Socket Set: For removing and installing bolts and nuts.

- Wrench Set: For holding bolts while tightening nuts.

- Screwdriver Set: For removing and installing screws.

- Jack or Lift: To support the slide out while replacing the rollers.

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands.

Steps for Replacing Rollers:

- Safety First: Disconnect the RV's power supply and ensure the slide out is properly supported before beginning the repair.

- Access the Rollers: Depending on your RV's slide out design, you may need to remove panels or covers to access the rollers.

- Support the Slide Out: Use a jack or lift to support the slide out and take the weight off the rollers.

- Remove the Old Rollers: Remove the bolts or screws that hold the old rollers in place.

- Install the New Rollers: Install the new rollers, making sure they are properly aligned and secured.

- Lower the Slide Out: Slowly lower the slide out onto the new rollers.

- Test the Slide Out: Extend and retract the slide out several times to ensure that it is moving smoothly.

- Reinstall Panels or Covers: Reinstall any panels or covers that you removed to access the rollers.

RV Slide Out Cable Repair and Maintenance

In some RV slide-out systems, cables play a crucial role in synchronizing the movement of different parts of the slide-out mechanism. These cables, often found in Schwintek slide-out systems, ensure that the slide-out extends and retracts evenly, preventing binding and damage. Maintaining these cables is essential for smooth and reliable operation.

Understanding Slide Out Cable Systems:

Slide-out cable systems typically consist of:

- Cables: High-strength steel cables that transmit force between different parts of the slide-out mechanism.

- Pulleys: Grooved wheels that guide the cables and change their direction.

- Tensioners: Devices that adjust the tension of the cables.

- Anchor Points: Points where the cables are attached to the slide-out frame and mechanism.

Common Cable Problems:

- Frays and Breaks: Cables can fray or break due to wear and tear, corrosion, or excessive stress.

- Loose Tension: Over time, the cables can lose tension, leading to slippage and uneven movement.

- Corrosion: Exposure to moisture and the elements can cause the cables to corrode, weakening them and reducing their lifespan.

- Pulley Problems: Pulleys can become worn, damaged, or seized, preventing the cables from moving smoothly.

- Improper Routing: Cables that are not routed properly can rub against other components, leading to wear and damage.

Diagnosing Cable Problems:

- Uneven Movement: The slide-out extends or retracts unevenly, with one side moving faster than the other.

- Slippage: The slide-out slips or jumps during operation.

- Visible Damage: Inspect the cables visually for any signs of fraying, corrosion, or damage.

- Loose Tension: Check the tension of the cables by pressing on them. They should feel tight and responsive.

- Pulley Inspection: Inspect the pulleys for any signs of wear, damage, or seizing.

Cable Maintenance:

- Regular Inspection: Inspect the cables regularly for any signs of fraying, corrosion, or damage.

- Tension Adjustment: Adjust the tension of the cables as needed to ensure even movement. Refer to your RV's owner's manual for instructions on how to adjust the cable tension.

- Lubrication: Lubricate the cables and pulleys with a silicone-based lubricant to reduce friction and prevent corrosion.

- Proper Routing: Ensure that the cables are routed properly and are not rubbing against other components.

Cable Repair and Replacement:

Repairing damaged cables is generally not recommended, as it can compromise their strength and reliability. In most cases, it's best to replace damaged cables. Replacing the cables is a more involved repair that may require the assistance of a qualified RV technician, especially with Schwintek systems which can be complex. The cost of replacement cables can vary depending on the type and size, but expect to pay between $20 and $100 per cable. You can find replacement cables at most RV supply stores or online retailers.

RV Slide Out Controller Repair Understanding the Electrical System

The RV slide-out controller is the brain of your slide-out system, managing the electrical signals that control the motor and other components. When the controller malfunctions, your slide-out may become unresponsive or exhibit erratic behavior. Understanding the electrical system and troubleshooting controller problems is crucial for maintaining your RV's functionality.

Understanding the Slide Out Controller:

The slide-out controller typically consists of:

- Microprocessor: The central processing unit that controls the operation of the slide-out system.

- Relays: Electrically operated switches that control the power to the motor and other components.

- Sensors: Devices that provide feedback to the controller about the position of the slide-out.

- Wiring Harness: A collection of wires that connect the controller to the motor, sensors, and other components.

Common Controller Problems:

- Controller Failure: The controller itself can fail due to electrical surges, overheating, or component failure.

- Wiring Problems: Loose connections, corroded wires, or damaged wiring can prevent the controller from functioning properly.

- Sensor Problems: Faulty sensors can provide incorrect feedback to the controller, causing it to malfunction.

- Relay Problems: Relays can become stuck or fail to operate properly, preventing the motor from receiving power.

- Power Supply Issues: Insufficient voltage or a faulty power supply can prevent the controller from operating properly.

Troubleshooting Controller Problems:

- Check the Power Supply: Ensure that the controller is receiving adequate voltage from the RV's battery or charging system. Use a multimeter to check the voltage at the controller terminals.

- Inspect the Wiring: Inspect the wiring connections to the controller for any signs of looseness, corrosion, or damage. Clean or repair any damaged connections.

- Check the Sensors: Test the sensors to ensure that they are functioning properly. Refer to your RV's owner's manual for instructions on how to test the sensors.

- Listen for Relay Clicks: When you operate the slide-out switch, listen for the sound of the relays clicking. If you don't hear the relays clicking, it could indicate a problem with the relays or the controller.

- Consult a Wiring Diagram: Refer to your RV's wiring diagram to help you troubleshoot the electrical system.

Controller Repair and Replacement:

Repairing a faulty slide-out controller is often not feasible, as it requires specialized equipment and expertise. In most cases, it's more cost-effective to replace the controller. Replacing the controller is a more involved repair that may require the assistance of a qualified RV technician. The cost of a replacement controller can vary depending on the type and features, but expect to pay between $100 and $500. You can find replacement controllers at most RV supply stores or online retailers.

RV Slide Out Room Adjustment Techniques Optimizing Space

RV slide-out rooms are designed to expand your living space, but sometimes they may not extend or retract fully, leaving you with less room than intended. Proper adjustment techniques can help optimize your slide-out room and ensure that it functions as intended.

Understanding Slide Out Adjustment:

Slide-out adjustment involves making fine-tuning adjustments to the slide-out mechanism to ensure that it extends and retracts fully and evenly. This may involve adjusting the rollers, tracks, gears, cables, or other components of the slide-out system.

Common Adjustment Issues:

- Incomplete Extension or Retraction: The slide-out does not extend or retract fully.

- Uneven Extension or Retraction: One side of the slide-out moves faster than the other.

- Binding: The slide-out gets stuck or binds in certain spots.

- Gaps: Gaps appear around the slide-out when it is fully extended or retracted.

- Rubbing: The slide-out rubs against the frame or other components.

Adjustment Techniques:

- Roller Adjustment: Adjusting the rollers can help to level the slide-out and ensure that it moves smoothly.

- Track Adjustment: Adjusting the tracks can help to align the slide-out and prevent it from binding.

- Gear Adjustment: Adjusting the gears can help to synchronize the movement of different parts of the slide-out mechanism.

- Cable Adjustment: Adjusting the cables can help to ensure that the slide-out extends and retracts evenly.

- Seal Adjustment: Adjusting the seals can help to prevent water leaks and drafts.

Tools You'll Need:

- Socket Set: For removing and installing bolts and nuts.

- Wrench Set: For holding bolts while tightening nuts.

- Screwdriver Set: For removing and installing screws.

- Level: To check the alignment of the slide-out.

- Measuring Tape: To measure the extension and retraction of the slide-out.

- RV Owner's Manual: To refer to specific adjustment instructions for your RV model.

Important Considerations:

- Refer to Your Owner's Manual: Always refer to your RV's owner's manual for specific adjustment instructions for your slide-out system.

- Work Safely: Disconnect the RV's power supply and ensure the slide-out is properly supported before beginning any adjustments.

- Make Small Adjustments: Make small adjustments and test the slide-out after each adjustment.

- Consult a Professional: If you are not comfortable making adjustments yourself, consult a qualified RV technician.

RV Slide Out Troubleshooting Guide Common Issues and Solutions

This comprehensive RV slide out troubleshooting guide will walk you through common problems and their solutions, empowering you to diagnose and address issues effectively. Remember safety first, always disconnect from power and consult your RV's manual before attempting any repairs.

Problem: Slide Out Won't Extend or Retract

Possible Causes:

- Dead Battery: Verify battery charge and connections.

- Blown Fuse or Tripped Breaker: Check the fuse panel or breaker box. Replace blown fuses with the correct amperage. Reset tripped breakers.

- Loose Wiring: Inspect wiring connections to the motor and controller. Tighten any loose connections.

- Faulty Switch: Test the slide out switch with a multimeter. Replace if necessary.

- Motor Failure: Listen for motor noise. If silent, the motor may be dead. Test with a multimeter or consult a technician.

- Obstruction: Check for obstructions preventing movement (e.g., debris, furniture).

Solutions:

- Charge or replace the battery. Clean battery terminals.

- Replace blown fuses or reset tripped breakers.

- Tighten loose wiring connections. Repair or replace damaged wires.

- Replace the faulty switch.

- Replace the faulty motor.

- Remove any obstructions.

Problem: Slide Out Moves Jerkily

Possible Causes:

- Lack of Lubrication: Insufficient lubrication on the slide out mechanism.

- Worn Rollers: Worn or damaged rollers causing uneven movement.

- Misaligned Tracks: Tracks that are out of alignment.

- Gear Problems: Worn or damaged gears.

- Cable Issues (Schwintek Systems): Frayed or loose cables.

Solutions:

- Lubricate the slide out mechanism with a dry-film lubricant.

- Replace worn or damaged rollers.

- Adjust the tracks to ensure proper alignment.

- Replace worn or damaged gears.

- Inspect and replace frayed or loose cables.

Problem: Slide Out Leaks When Retracted

Possible Causes:

- Damaged Seals: Cracked, torn, or worn seals.

- Improper Seal Seating: Seals not properly seated against the slide out flange.

- Debris: Debris preventing the seals from seating properly.

Solutions:

- Replace damaged seals.

- Clean the seals and flange and ensure proper seating.

- Remove any debris from the seals and flange.

Problem: Slide Out Makes Loud Noises

Possible Causes:

- Lack of Lubrication: Insufficient lubrication on the slide out mechanism.

- Worn Rollers: Worn or damaged rollers.

- Misaligned Tracks: Misaligned tracks.

- Gear Problems: Worn or damaged gears.

- Debris: Debris caught in the slide out mechanism.

Solutions:

- Lubricate the slide out mechanism.

- Replace worn or damaged rollers.

- Adjust the tracks.

- Replace worn or damaged gears.

- Remove any debris.

Choosing the Right RV Slide Out Repair Service Professional Advice

When faced with complex RV slide-out repairs, enlisting the help of a qualified service professional is often the best course of action. However, choosing the right repair service can be challenging. Here's what to look for:

Factors to Consider:

- Experience and Expertise: Look for a service with extensive experience in RV slide-out repair, preferably with certifications or training from reputable organizations like RVIA.

- Reputation: Check online reviews and ask for recommendations from other RVers. A good reputation is a strong indicator of quality service.

- Specialization: Does the service specialize in slide-out repairs, or is it just one of many services they offer? A specialized service is more likely to have the expertise and equipment needed to handle complex repairs.

- Warranty: Does the service offer a warranty on their repairs? A warranty provides peace of mind and protects you from future problems.

- Pricing: Get multiple quotes from different services and compare their pricing. Be wary of services that offer extremely low prices, as this may indicate low-quality work.

- Communication: Choose a service that communicates clearly and keeps you informed throughout the repair process.

- Insurance: Ensure that the service is properly insured to protect you from liability in case of accidents or damage.

Questions to Ask:

- "How many years of experience do you have repairing RV slide-outs?"

- "Are you certified or trained in RV slide-out repair?"

- "Do you specialize in slide-out repairs?"

- "What is your diagnostic process?"

- "Do you offer a warranty on your

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)